蒸汽排放消声器(消音器系列 SILENCER SERIES)

本公司生产的XSQ系列消声器可满足各种参数锅炉向空排汽、安全阀排汽及锅炉送风机进口的降噪消声要求,同时也广泛用于石油、化工、冶金、纺织等工业的锅炉蒸汽排放及其他气体消声排放,使之达到工业企业噪声标准要求。其特点如下:

1、采用多级消声,消声量大,排汽消声器35~40分贝;放空消声器可达25~30分贝。

2、体积小,重量轻,安装简便,易维护。

3、XSO系列,筒体采用优质不锈钢或碳钢,具有足够高的强度和耐腐蚀性。

4、能单独固定、吸收排汽管道的垂直及水平热位移,使排汽管道不因消声器的安装而受到额外的荷载,保证排汽管道在热能工作下的安全性。

蒸汽排汽消声器(XSO-B型) Vent silencer for steam

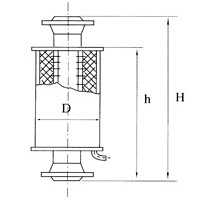

蒸汽排放消声器“尺寸表” Dimension table:

DN | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

H | 3000 | 3000 | 3500 | 3800 | 3800 | 4200 | 4200 |

h | 2384 | 2384 | 2900 | 3200 | 3200 | 3400 | 3400 |

D | 260 | 312 | 412 | 551 | 623 | 809 | 972 |

蒸汽排放消声器“特征” Features

1. 消声量满足《工业企业噪声卫生标准》的要求;

"The noise muffling volume to meet the health standards" requirements of industrial enterprises;

2、消声降噪音的同时不影响设备的流量,安全泄压释放不影响安全阀的起跳和回座;

Acoustic noise reduction without affecting the traffic safety relief devices, release without affecting the safety valve popping and back seat;

3、结构性能适应瞬间排放高温、高压蒸汽的冲击。

Structure and properties of high temperature and high pressure steam to instantaneous emissions impact;

蒸汽排放消声器“原理” Principle

1. 采用了抗、喷、阻的消声原理,以大孔扩容降压保证安全门排汽顺畅,多层次穿孔吸声;

The noise reduction principle of anti, spray, resistance to high hole expansion, ensure the safety valve vent smoothly, multi-level perforated.

2. 结合阻性消声原理,让蒸汽声波进入多孔吸声材料中的无数小孔内,激发多孔材料分子震动,使声能为了克服摩擦阻力和粘滞力而变成热能;

Combined with the noise reduction principle, let the steam sound waves into numerous small holes of porous sound absorbing material in the excited molecular porous material vibration, the energy to overcome the frictional resistance and viscous force into heat;

3. 小孔喷射把具有宽频带的排汽噪声推向人耳不敏感的超高频区域,并加速声音衰减。

The hole injection with exhaust noise broad band to the human ear is insensitive to the ultra high frequency region, and accelerate the sound attenuation;

蒸汽排放消声器“应用范围” The scope of application

1. 发电厂;

Power plant;

2. 热电厂;

Thermal power plant;

3. 钢铁厂;

Iron and steel plant;

4. 化工厂。

Chemical plant.

蒸汽排放消声器“作用” Effect

对空排汽、锅筒安全阀和排汽阀及各类热力蒸汽管道的蒸汽对空排放时的有效消声。

Exhaust steam, boiler drum safety valve and exhaust valve and all kinds of heating steam pipe steam on effective silencing air emissions.

订购蒸汽排放消声器“提供参数” To provide parameters

排汽量多少(t/h)

The number of exhaust volume (t/h)

排汽压力(MPa)

Exhaust pressure (MPa)

排汽温度(℃)

Exhaust temperature (c)

排汽管规格(φ×δ)

The exhaust pipe specifications (diameter * δ)

蒸汽排放消声器“安装须知” Installation notes

1. 应垂直于炉顶安装,如图所示,用型钢支架将消声器固定支座或落地支腿与炉顶相固定;

Should be installed perpendicular to the top, as shown in the figure, the muffler fixed bearing or landing leg and the top is fixed with steel support;

2. 为增加炉顶高空的抗风能力,对于体形较大消声器应采用支承式,及在消声器前的排汽管装一段膨胀弯管以吸收热胀。

As the wind increased top altitude, for larger muffler should adopt bearing type, and the front muffler exhaust steam pipe installed an expansion bend to absorb thermal expansion.

3. 下部的排水口应畅通接到地沟,不应装配阀门。

The lower part of the outlet should be smooth to the trench, should not the valve assembly.

4. 在炉顶平台,对于TA、TB、TD系列通孔型抗喷阻消声器及FHX系列复合式消声器排汽出口在顶部,应用薄板(不锈钢板、镀锌钢板)制作防雨罩一只及周边加装防护网罩。

At the top of the platform, for TA, TB, TD series of through hole spray resistance muffler and FHX series of complex muffler exhaust outlet at the top, with the thin plate (stainless steel plate, galvanized steel) making rain cover a and surrounding with protective net cover.

5. 安全阀或排汽阀与消声器这间的排汽管道上应没有疏水点。

Safety valve or the exhaust valve and the exhaust muffler pipe should be no drainage point.

6. 对于PA系列小孔消声器,安装前应以防小孔堵塞,如新装的锅炉或恢复性检修,投入运行前应先安装吹管集粒器,冲管消声器对管路系统进行吹管,清除管道内的杂物。

For the PA series of micropore muffler, before installation should be to prevent pore blockage, such as the newly installed boiler or restorative overhaul, put into operation before the installation of wind particle collecting device, the flushing pipe muffler was blowing on the pipeline system, remove the pipe.

风机消音器达到良好的消音效果

2017-03-23蒸汽消声器,以避免蒸气和液体的振动和噪音

2016-08-02排气消声器创造理想的环境,安装说明要知道

2017-03-23浮动出油装置意味着好油的质量检查

2016-06-29如何判断好坏消声装置

2016-05-31磁性浮子液位计和分析工业热电偶安装注意事项的特点

2016-08-02快速接头全面了解

2016-06-09日常维护检查磁性浮子液位计非常重要

2016-08-02闲聊消声器微穿孔消声器

2016-05-31